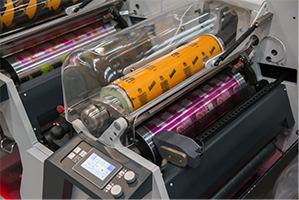

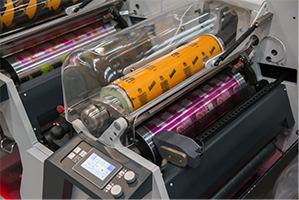

Italy : Omet has said that the digalised printing process of the Omet X6.0 has allowed its users to reduce waste of time and material usually needed to start a new job.

“The line can get into perfect register in less than 10 meters when starting a new job. This result comes from a combination of special functions patented by Omet to provide more production flexibility and to ease operations of set-up, job changing and registration, drastically reducing expensive production downtimes for customers. The operator gets the maximum performance with the minimum effort,” said a company release.

The on-the-fly change allows the printing units get adjusted independently, getting into right printing position, immediately. According to Omet, the combination with the Multivision system allows color by colour registration in real time with no additional waste thanks to set of Smart Cameras, one on each flexo unit. “These two systems are enhanced by the Cruise Control, which allows the automatic positioning of the printing pressures at every change of speed, substrate thickness and repeat length.”