to ease recycling process

Clariant has teamed up with pigment supplier Merck and polymer producer SABIC to develop laser-marking technology and materials to ease the recycling process for flexible polyethylene (LDPE, LLDPE) packaging film.

For the partnership, SABIC will be supplying a range of polymers for packaging, including its “certified circular polymers”, which use Tacoil feedstock, an oil produced through the chemical recycling of low quality, mixed plastic waste.

“There is a growing demand for clean, high-quality recycled PE,” said Chun-Yip Pang, Clariant’s global product manager additive masterbatches, adding that despite the increasing rate of recycling for PE films, there still remains a number of challenges.”

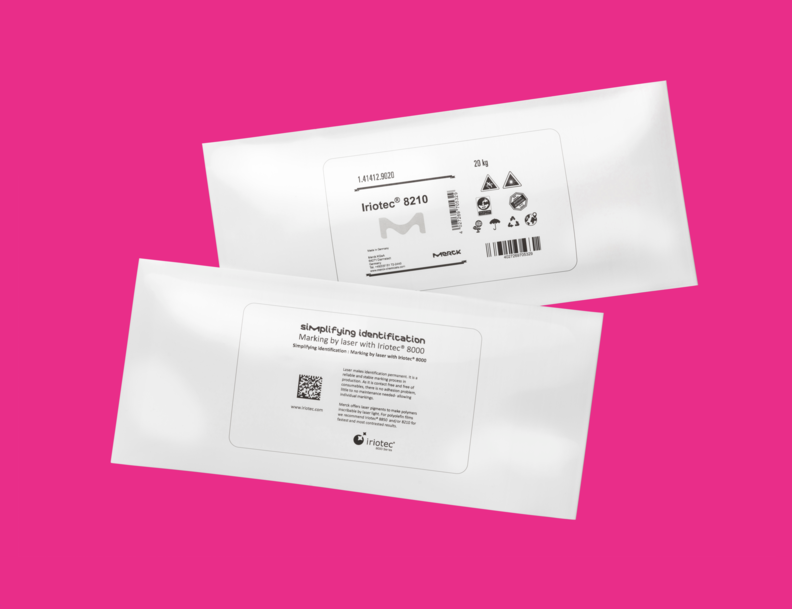

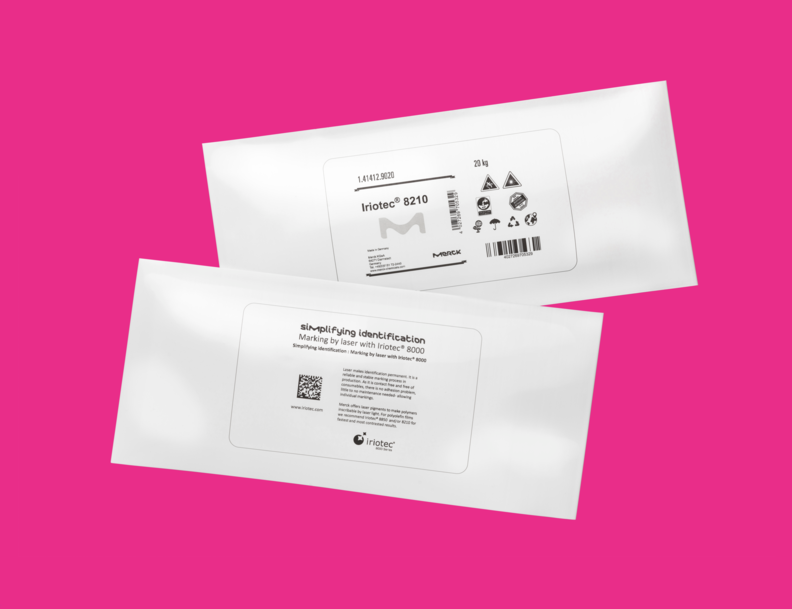

Laser-sensitive Iriotec pigments and marking expertise are provided by Merck, while Clariant will contribute with its additive master-batch formulations developed for use in the film extrusion process.

Pang added, “This collaboration is focused on eliminating the printing ink used for tracking, shelf-life, bar codes and other variable information that must be placed on almost any package on the market. Less ink means less contamination when it comes to recycling.”