Kenya: Silafrica, a leading packaging supplier to East Africa and surrounding regions has taken its environmental responsibility to the next level following the introduction of a new manufacturing process for beverage closures, which cuts energy consumption by more than 31% when compared to their previous injection molding process.

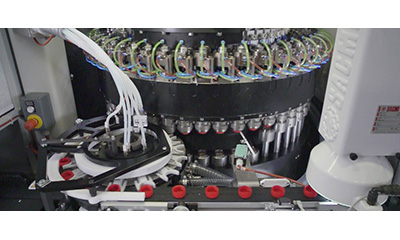

Installed late last year in the company’s Tanzania facility, for initial testing, the high-speed CCM24SB press line from Italian-based machinery manufacturer SACMI produces closures of higher quality at a lower cost. Extremely lightweight and requiring far fewer packaging materials, it is but another example of the Silafrica mission as a responsible global citizen.

According to Silafrica, the new state-of-the-art high-speed rotary compression molding machine has the capacity to produce more than 400 million beverage closures annually for standard single and multi-use beverage bottles.

“Rotary compression molding is a far superior process for producing high-speed, high-quality beverage closures at a much lower cost when compared to other processes,” commented Akshay Shah, group managing director of Silafrica.

“And the best part,” he adds, “is that the process yields lighter weight, one-piece closures that require less material and use much less energy to produce. For our many beverage customers, sustainability has become a top priority in their packaging strategy. As their valued supply chain partner, we are continuously improving our facilities and services to enable them to meet and exceed those goals.”

Following the successful test runs, Silafrica now produces closures for Coca-Cola, Pepsi and several large regional beverage brands who serve consumers throughout the greater East African region. Other notable customers of Silafrica include Diageo, Heineken, Unilever, SAB Miller, AB InBev, Daima and many more.

Silafrica’s three facilities strategically located throughout East Africa are all ISO 9001 certified and FSSC 22000 certified for food safety and quality standards, as well as Ecovadis, rated for sustainability. Each facility is also equipped with its own water and power supply, and is supported by a regional, trained workforce.