PureCycle Technologies has partnered with global industrial manufacturer, Milliken & Company, and the food and beverage global giant, Nestlé in South Africa, to open its first plant to restore used polypropylene (PP) plastic to ‘virgin-like’ quality with a revolutionary recycling method.

PureCycle Technologies has partnered with global industrial manufacturer, Milliken & Company, and the food and beverage global giant, Nestlé in South Africa, to open its first plant to restore used polypropylene (PP) plastic to ‘virgin-like’ quality with a revolutionary recycling method.

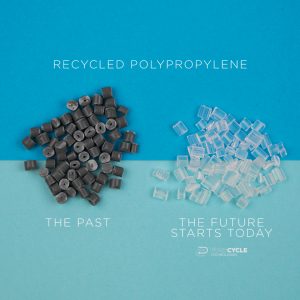

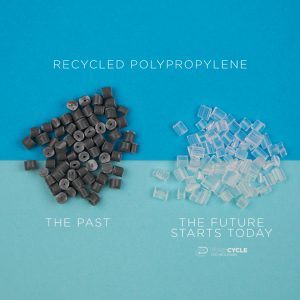

PureCycle’s patented recycling process, developed and licensed by Procter & Gamble (P&G), separates color, odor and other contaminants from plastic waste feedstock to transform it into virgin-like resin. Milliken, whose additives will play a critical role in reinvigorating recycled polypropylene, has formed an exclusive supply relationship with PureCycle to help solve the plastics end-of-life challenge. Nestlé is working with PureCycle to develop new packaging materials that help avoid plastic waste, in line with the company’s commitment to make 100% of its packaging recyclable or reusable by 2025.

“These partners are helping us accelerate as we bring this solution to the market,” said Mike Otworth, CEO of PureCycle Technologies. “This is a validation of our method, and it will help us continue to move even more quickly as we make plastics recycling a reality.”

Bringing consumer market knowledge and technical expertise, Milliken and Nestlé help PureCycle work towards delivering the world’s first virgin-like recycled polypropylene. “The use of Milliken’s additives will help to ensure that PureCycle’s Ultra Pure Recycled Polypropylene (UPRP) is of the highest quality and adds the maximum value to brand owners and consumers. We believe that this partnership will further differentiate PureCycle as both a leading reclaimer and producer of polypropylene,” continues Otworth.

“Milliken understands that creating a sustainable future requires meaningful collaboration with other industry pioneers,” said Halsey Cook, president and CEO of Milliken & Company. “We believe PureCycle’s technology combined with Milliken’s leading plastic additives provide a transformative opportunity to elevate the viability of recycled polypropylene and help solve the plastics end-of-life challenge.”

Today, about 20 percent of polyethylene terephthalate (PET), which is commonly used to make plastic bottles and other consumer goods, is recycled. By contrast, less than 1 percent of polypropylene plastic is currently recycled.

PureCycle’s first plant in Lawrence County, Ohio will recycle 119 million pounds of polypropylene, producing over 105 million pounds per year starting in 2021. PureCycle Technologies will make high-quality, recycled PP widely available for purchase across industries.

This technology licensed by P&G demonstrates P&G’s commitment to sustainability and helps in achieving P&G’s recycling goals – doubling the use of recycled resin in plastic packaging and ensuring 90 percent of product packaging is either recyclable or programs are in place to create the ability to recycle it.

“This technology has the capacity to revolutionize the plastics recycling industry by enabling P&G and companies around the world to tap into sources of recycled plastics that deliver nearly identical performance and properties as virgin materials in a broad range of applications,” said Kathy Fish, Chief Research, Development and Innovation Officer, Procter & Gamble.

The global polypropylene market is valued at more than $80 billion, according to Transparency Market research, and is on track to reach $133.3 billion by 2023.