Kodak has rolled out its process-free technology to Asia, Australia and New Zealand, Middle East, and Europe

Dubai Kodak has announced that its Sonora UV process-free plate, the latest addition to the company’s process-free technology portfolio, is now available in many regions of the world.

Dubai Kodak has announced that its Sonora UV process-free plate, the latest addition to the company’s process-free technology portfolio, is now available in many regions of the world.

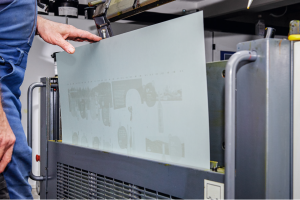

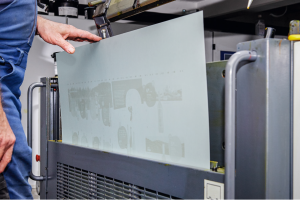

Sonora UV plates expand the capability of Kodak’s process-free plate portfolio to an even wider group of print service providers. They can deliver longer-run lengths for UV print applications than other process free plate, catering or up to 30,000 impressions, according to Kodak.

This allows printers to take advantage of both the environmental and economic benefits of process free plates and the expanded set of opportunities associated with UV technology, including flexibility, high print quality, and faster drying times. Sonora UV is based on technology used in the Sonora XJ process-free plate, commercially available in Japan since 2016. Sonora plates, like the flagship XP version, work with existing press setups and sequences.

Kodak claims Sonora UV plates meet the demands of UV print applications increasingly used by today’s packaging and commercial printers and also enable printers to take advantage of both the environmental and economic benefits of process free plates.

“Kodak is committed to investing in R&D that advances the capabilities of print service providers and equips them to offer a wider range of applications and tackle new markets while accomplishing all that in the most environmentally way possible,” said Richard Rindo, general manager worldwide offset print and vice president print systems division, Kodak.

“Over 3,000 customers around the world are yielding significant cost and environmental benefits from Sonora and with Kodak manufacturing facilities now located in the USA, Europe, Japan and China, printers across the globe benefit from faster supply, support and customer service.”