Label printers, especially those working in flexo, should explore how printed electronics can promote brands, combat counterfeiting, and even ensure patients take their medicine as instructed, says the trade association FINAT.

Printed electronics – and how packaging can continue to drive their development – was the topic of a webinar held in March by FINAT, an umbrella organisation for the self-adhesive label industry.

Packaging has already powered the emergence of printed electronics – from RFID to QR codes and other digitally ‘readable’ data – and the printing expertise, specialist materials, and conductive inks for reliably creating these ‘intelligent’ functions are long-standing specialties of the label production chain, said FINAT.

Packaging has already powered the emergence of printed electronics – from RFID to QR codes and other digitally ‘readable’ data – and the printing expertise, specialist materials, and conductive inks for reliably creating these ‘intelligent’ functions are long-standing specialties of the label production chain, said FINAT.

At its recent members-only webinar, the association gave an update on existing applications and the potential opportunities in printed electronics for printers across the narrow-web flexo market.

Chris Jones of Novalia, a UK-based company specialised in conductive print and capacitive touch, told label industry delegates to seek innovative combinations of current technologies.

“By combining extant mainstream equipment, consumables, and expertise, they can create state-of-the-art printed electronics that, in addition to scannability, bring the dimensions of touch, sound, and vision into play to add real additional functionality or even ‘must have’ desirability to a product or its packaging,” he said.

“Today, as well as printed circuit boards and transistors, print can deliver a variety of other mainstream applications – including lighting, LEDs, photovoltaics, and even skincare patches – and features strongly in automotive, aviation, architectural and military applications and in pharmaceuticals and healthcare, toys, music, and of course brand protection and anti-counterfeiting.”

Smartphone interaction

In markets where most consumers carry a smartphone, printed electronics already offer a host of enticing opportunities for interaction with what might appear, for example, to be simply displays, printed posters, or outdoor advertising.

As part of the launch for its new Flavour Shots herbs and spices range, Schwartz used a ‘sonic poster’ featuring Novalia’s capacitive touch technology, said Jones.

When the paper poster is touched, it plays music wirelessly through a Bluetooth-enabled smartphone or tablet. Touching the artwork on different spots triggers musical chords designed to add an extra level of engagement with the new Schwartz products.

Conductive inks enable the surface of the paper to be turned into an interactive interface, so that new dimensions such as sound or movement can be added to display print, making consumers more aware of – and interested in – the product.

Added-value packaging

But packaging also offers many examples of the creative application of such technologies, said Jones.

“For example, a box of tissues that featured a playable piano keyboard on the side of the packaging, and multiple-pack secondary packaging for beers and cigarettes that also carried special printed ‘touch’ and ‘connectivity’ features. What consumer could resist the added value of such packaging?”

On a more serious note, pharmaceutical and healthcare applications add user-friendliness to alert patients to take their blister-packed medication – and enable the pharmacist/dispenser to check, thanks to a microprocessor in the pack, that the drugs were in fact taken at the right time in the right quantities.

Flexo’s winning features

For volume production of printed electronics, narrow-web label printers are particularly well positioned as providers, said Jones.

“While screen and gravure have their place in certain application areas, flexo has proved itself the most attractive print process for the job,” he explained.

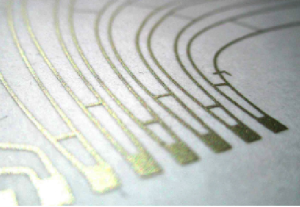

“Its combination of good print speeds and ease of repeatability; the high, consistent application weight of wet ink that flexo achieves; and the good range of available flexible, inexpensive substrates (paper, PP, PET), constitute an ideal combination.

“The conductive pigments themselves represent an additional consideration for the flexo printer – both in practical and cost terms – and, additionally, drying the ink is a key factor. Currently, evaporative solvent and water-based drying provide the desired characteristics. UV ink curing remains a challenge, because at this time it does not pack the ink particles together sufficiently.

“The process of printing conductive inks embraces, in summation, anilox specification, production speed, drying, and press consumables – all of which can affect the ‘sheet resistance’ of the conductive inks – the characteristic which is at the heart of a good result.”

Offering more to brand owners

As printers look to extend their services to brand owners, printed electronics should clearly be high on their list of options.

“There is certainly a considerable and growing interest from narrow-web label printers in extending the range of specialist capabilities they can offer to brand owners,” said Jones.

“Their skills base and pressroom equipment can enable them to deliver printed items incorporating printed electronics in a variety of creative forms that go well beyond traditional functional/industrial applications and conventional label print.”

Founded in Paris in 1958 with headquarters in the Hague (The Netherlands), FINAT is the worldwide association for manufacturers of self-adhesive labels and related products and services with more than 500 members in over 50 countries around the world.