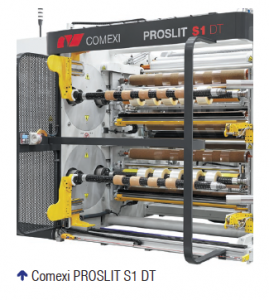

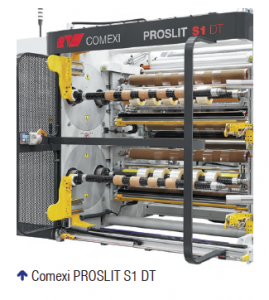

Comexi Group, a leading specialist in machinery solutions for the flexible packaging industry, announced on 30 June that it has developed the PROSLIT S1 DT, a double turret slitter-rewinder that can increase productivity and energy efficiency.

Plants can boost their production by 30% by replacing a Comexi PROSLIT Eikon with the new machine, said Comexi.

The PROSLIT S1 DT runs at up to 800m/min with new and shorter acceleration ramps as well as improved and faster turret-change. In addition, the machine offers an energy saving of 4–6% over the previous model, said its maker.

Comexi’s R&D department developed the new slitter-rewinder starting from the Comexi PROSLIT Eikon machine, which has more than 100 installations.

The machine’s tension range has been extended for a wider gamut of materials. It also has a new support arm system for turret changeover rotation standardised in all widths.

The PROSLIT S1 DT arm allows rotating in both sides: top and bottom. The shaft end in cantilever arrangement is supported during the turret’s rotation on a base that keeps it level and fixed. These arm improvements increase shaft life and simplify operations, according to Comexi.

In addition, the PROSLIT S1 DT offers users the option of adding fully automated download and palletising.

Comexi claims that the PROSLIT S1 DT is getting wide acceptance in the market. As of June 2014, and from the sale of the first unit in late 2013, the Catalan company has sold 12 units to customers in Scandinavia, Spain, Mexico, Peru, India, Iran and Turkey.